Armor is one of the simplest things to manufacture, yet it holds some of the most complex results.

A 5 cm plate of steel is rather easy to produce, but analyzing how well it will perform under a wide variety of types of damage in different orders is rather difficult.

There are three main methods of damage: projectile, photonic, and plasma. Generally speaking, given equal amounts of energy, plasma damage is the least effective in many cases, and projectile damage tends to be the most effective. These differences vary significantly and may even reverse depending on the type of armor, however.

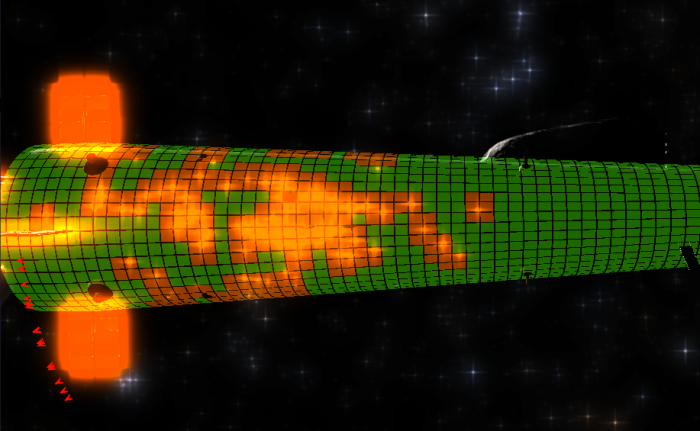

When a projectile hits armor, there are numerous ways that it may affect the armor. If the projectile does not penetrate, it can fracture the armor anyways, either where the bullet hit or on the other side of the armor. It could spall fragments off the inside of the armor, which can cause damage to internal compartments. And all of these scenarios are possible too if the projectile does fully penetrate.

Of course, with hypervelocity projectiles, in many cases, the projectile will shatter into plasma upon hitting. Not only that, the armor may shatter into plasma too. An interesting effect of this (which is modeled in Children of a Dead Earth) is that in certain cases, more armor can detrimental. Too much armor can get shocked into plasma or spallations and inflict even more damage than a thinner armor plate.

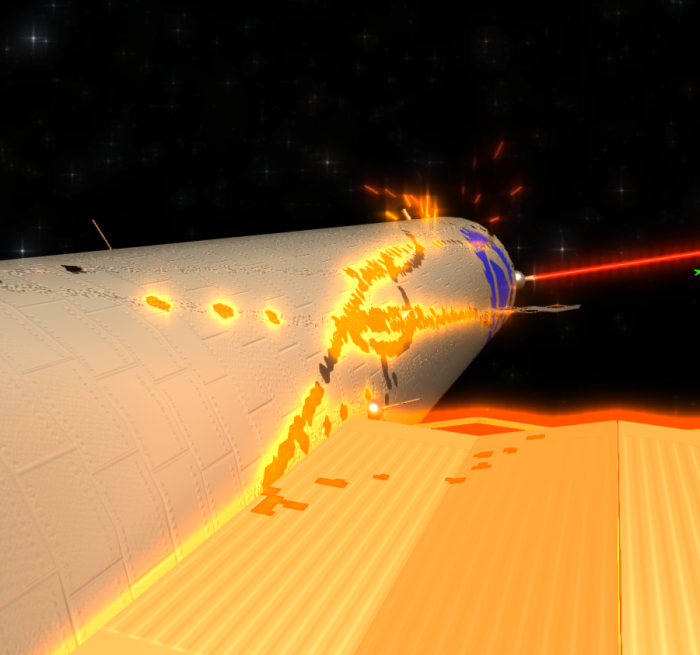

Laser damage is somewhat simpler. The primary method by which photons inflict damage is by ablating away the armor, causing material to melt, evaporate, or sublimate away.

Alternatively, a pulsed laser could be used to trigger shockwaves from the rapid expansion of the affected armor material. In this way, lasers can be used to inflict mechanical damage on the armor. A very thorough discussion on laser effects on armor can be found here.

Determining a model for how well a piece of armor reacts to every different scenario (or combination of scenarios) is rather difficult. On top of the different types of damage, there are many different kinds of armor materials and design choices.

Material properties that are important to armor materials follow.

The Ultimate Tensile Strength of a material is the capacity of that material to withstand tension, or being pulled apart. The Yield Strength, or the stress point at which plastic deformation of the material begins, is another metric which very important to determining the effect of mechanical damage.

The Density of a material plays a key role in resisting damage, particularly projectile impacts. One interesting point of note is that high density Whipple Shields perform worse due to a greater amount of Whipple Shield material being shocked into plasma, and hitting the main armor.

Against melt ablation by lasers, very different properties are used. Often, material strength is more or less irrelevant against laser damage. Instead, high Melting Points, Boiling Points, and Specific Heat Capacities are of crucial importance for armor to resist heating. All of these quantities allow the material to absorb more energy without failing.

Alternatively, some materials can get away with very poor heat resistance by instead having a very high Thermal Conductivity. If the material conducts heat away fast enough, a laser can dump energy into the material all day and never heat it up, as the material will conduct the heat away to surrounding armor tiles.

And of course, a number of other properties play a minor role in determining damage, like the Elastic Modulus and Shear Modulus. But generally when choosing armor, your main concern should be a high Ultimate Tensile Strength and a high Melting Point.

So with those properties in mind, what material is best to use for armor?

Consider the material used for a single monolithic plate. Common choices are metals like lightweight Aluminum and Titanium, or the very dense Depleted Uranium.

Alternatively, metal alloys like Steel, particularly high strength steels like Maraging Steel make for great armor. However, on Earth, high density is valuable for lower volume, but in space, low density armor is more important, as armor can and will drastically affect your spacecrafts mass ratio.

This means ceramics like Reinforced Carbon-Carbon or Boron Nitride see use everywhere in space. They tend to be somewhat weaker than many high strength alloys, but their low density and resistance against laser damage more than makes up for it. On top of that, they are extremely cheap. In practice, ceramic armor tends to be the most common spacecraft armor.

Synthetic fibers like Aramid, which includes Kevlar, Technora, and Twaron have exceptional strength against projectile damage while having very low density as well. On the other hand, they suffer badly against laser damage, having rather low melting points.

Then there are the more exotic materials. UHMWPE, or Ultra-High Molecular Weight Polyethylene, is a plastic which has enormous strength and incredible low density. Similar to Aramids, though, its melting point is rather low. Nanocomposites tend to very strong as well, but are difficult and expensive to manufacture. And of course, you can use Aerogel in game, though its usefulness as armor is questionable. Same with Metallic Microlattice.

A few materials are omitted, most prominently, Carbon Nanotubes (CNTs) and Carbyne. CNTs promise incredible strength, but with today’s technology, they are limited to bulk use. This entails essentially crushing a pile of CNTs together and hoping for the best, which performs very poorly compared to the strength of a single CNT. It is unclear if achieving CNT strength on a macro scale is possible or just a pipe dream. In all likelihood, they will likely be used as a way to bolster existing material strengths.

But armor is more than just a single plate of the strongest stuff you can find.

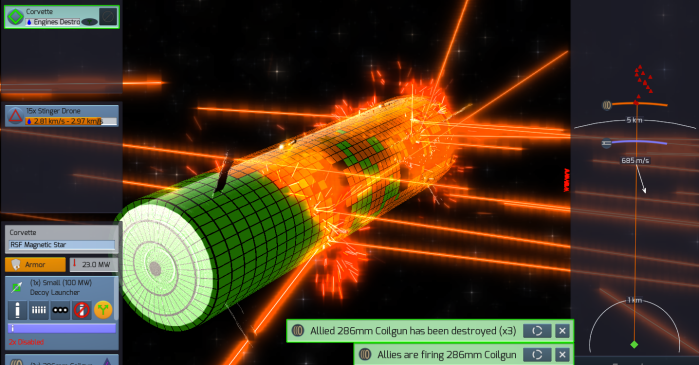

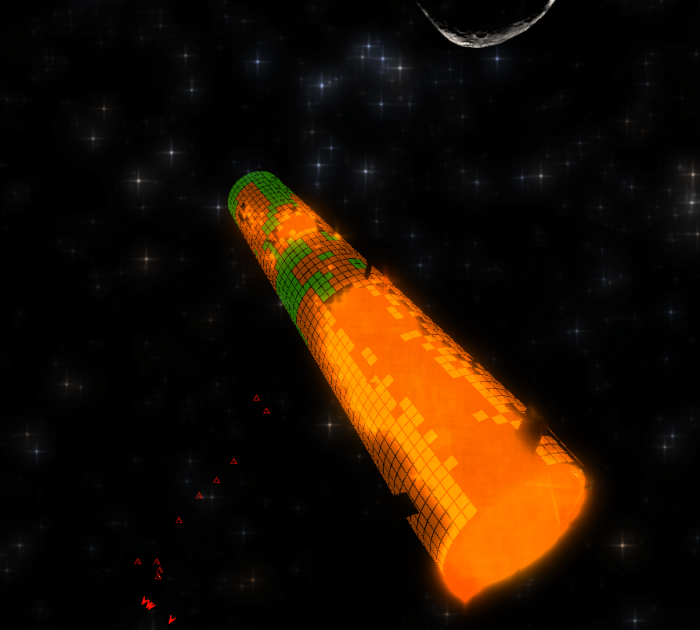

Whipple Shields are simple, cheap, and very effective. They are a specialized case of Spaced Armor. A thin plate of low density material spaced out far off from the main armor can shock incoming hypervelocity projectiles into plasma. The purpose of the spacing is to allow time for the plasma to expand into a greater area, and thus spread its damage thin.

In practice, Whipple Shields delay the inevitable. When the enemy is dumping a thousand bullets per minute at you, your Whipple Shield is going to get demolished very quickly. However, they buy you a small amount of time (less than a minute), and those tens of seconds might be exactly what you need to get in close with more powerful, closer range weapons.

Composite Armor is a fancy term for multiple layers of very different materials. As shown above, different materials perform better under different situations, so having composite armor is a way to have the best armor for each situations. In Children of a Dead Earth, each layer can be spaced out as well, combining Composite Armor with Spaced Armor/Whipple Shields.

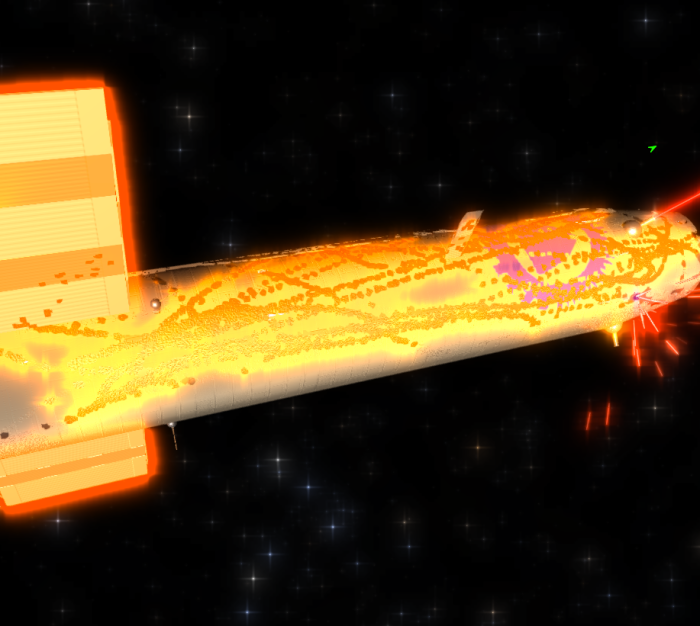

Sloped Armor is simple, cheap, and absolutely crucial. Simply angling the armor plates can have a tremendous effect on survivability. This is not just because the effective armor thickness increases with the angle, but also because it causes projectiles to ricochet, deform, or deflect. Sloped armor is arguably the most effective defensive measure.

In practice, missiles with extremely pointy faces survived far longer against enemy point defenses than missiles with flat faces. I discovered this when one of my alpha testers pointed out that between two of the smallest missiles, one with a tiny flak payload and one with a tiny nuclear payload, the flak missiles were surviving at 10x the rate of the nuclear missiles. As it turned out, the flak payload with long and thin, and convex armor hull wrapped it into a point, while the nuclear payload with short and fat, leading to a flat face.

All missile designs were given a sharp nose after that.

There are a few more design choices not in Children of a Dead Earth but should be mentioned for completeness.

Slat Armor uses a cheap grid around the armor to deform explosive projectiles. In space, however, most payloads are detonated before colliding, and explosive projectiles are already weak in space. Slat armor is easily defeated by Tandem Charges.

Reactive Armor layers the armor with explosives which detonate outwards when hit. While effective against incoming explosive payloads, again, explosive payloads are not used nearly as much as nuclear payloads and simple projectiles. Additionally, this armor needs to be outside of any Whipple Shield, lest the Whipple Shield blasts out numerous tiles with each expanding burst of plasma. Not a very effective armor if the enemy is carpeting you with bullets. Also defeated by Tandem Charges.

Electric Armor is two plates of armor separated by an electrical insulator, and one side charged. When a bullet hits and closes the circuit between the two plates, the electrical discharge will vaporize the bullet or even turn it into plasma. This would require an additional armor layer beyond the Electric Armor to shrug off the plasma, likely spaced out to let the plasma spread thin. While promising, this technology does not exist in any current form, and its limitations are unclear.

That’s all for armor! Armoring your spacecraft designs is very simple, but the ramifications end up being very complex. And as with many designs, optimal solutions are never as obvious as you may think.